Whether you’re a power plant, agricultural company, construction site, or mining operation, you’ve probably needed to perform a bulk bag calculation to determine what size bag would be necessary for the volume of waste or product you need to contain.

Learning how to calculate bulk bag capacity is not a complicated undertaking, but it does require you to know what super sack sizes are available and the formula professionals use to determine the capacity of each bag.

If you are on the hunt for a bulk bag capacity calculator, or you simply want to learn how to calculate a bulk bag capacity, you’re in the right place. Keep reading for all that information and more.

How to Calculate a Bulk Bag’s Capacity

The capacity of a bulk bag refers to how much of a specific product or material your chosen bag can hold. Sometimes, even to determine the type of bag you require, you need to establish a base volume.

It’s important to note that bulk bag capacities are often provided in cubic meters. Some companies may also display cubic feet. If your preferred calculator gives you the answer in cubic feet and you require it in cubic meters, or vice versa, you can use an online calculator to change the volume to what is most appropriate for your situation.

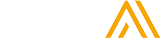

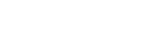

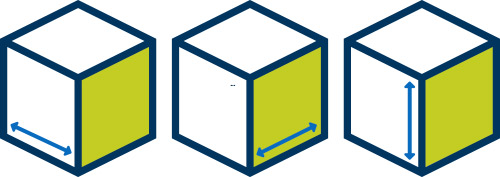

Part of the calculation process also involves identifying a bulk bag’s dimension to determine its volume. Most bulk bag volumes are worked out with a specific formula based on their length, height, and width.

Given that most FIBCs feature polypropylene or woven polyethylene, some bulging does occur. This means that while using a bulk bag calculator can determine the volumetric capacity, you can generally fit slightly more materials into the bag than specified in the calculation.

FIBC Bags Formula

What you will often see mentioned in any FIBC bag capacity calculation guide is a basic volume formula: volume = length x width x height.

This means that an average bulk bag of 35 inches x 35 inches x 35 inches can hold up to 29.6 cubic feet, or 51,148 cubic inches, of your chosen materials. If you were to choose another bag size, you would measure the height, length, and width to determine a different volume.

Factors Affecting a Bulk Bag’s Capacity

After using a standard FIBC bag weight calculation to determine the volume capacity of your materials, you may think that the calculated volume is exactly what you will fit into your bulk bags. However, many other factors can affect your chosen bulk bag’s capacity.

- Weight

- Volume and weight don’t always work in harmony. You may have calculated 25 cubic feet will fit in one bulk bag, but 25 cubic feet of your chosen material may exceed the bag’s weight limit. It’s worth consulting with the experts at PacTec to determine the most appropriate packaging type for your specific materials.

- Material Density

- The higher your materials’ density, the lower the bag’s capacity. Keep this in mind when choosing your bulk bags.

- Bag Loops

- Lifting loops are a necessary part of most bulk bags, but they can also impact the bag’s capacity. Bags require extra clearance with lifting loops, equal to the bag and loop height.

- Rounding

- Bulk bag material is flexible, which means some rounding can occur at the corners to diminish their capacity. Talk to us about different bag designs like baffled bags with reinforced corner panels. Otherwise, factor this into your calculations when determining how many bulk bags you require.

- Inlet Type

- Your bulk bag’s filling inlet can be a factor in its capacity. An open-top bag can allow for more flexibility with capacity. If you purchase bags styled with spout tops, these may take up space that would otherwise be consumed by your materials.

In Conclusion

Using a bulk bag calculator can make sure that you choose a bulk bag that’s safe, usable, and functional for your needs. There doesn’t have to be any guesswork involved, nor does there need to be any complicated formulas.

All you need to do is use an FIBC bag weight calculation tool with your measurements to understand the best bulk bag for your needs. You can then consider a few other factors that affect FIBC capacity, such as weight and density, before making an informed decision.

All that’s left to do now is contact the experts in waste packaging solutions to order the product you need and you’ll be on your way to an approved packaging solution.