The federal government, EPA, OSHA, and states have all passed laws and regulations that place strict requirements on businesses concerning the containment of certain hazardous liquids and chemicals, such as oil and gasoline. The goal aimed at preventing accidentally spilled or leaked hazardous materials from contaminating the environment, including soil and groundwater, and from harming human health. The rules are very precise requirements for calculating secondary container volume requirements based on the size of the primary storage container, but, fortunately, you can use a secondary containment calculator that accommodates various job site setups.

Safe Haven for Spilled Hazardous Liquids

Think of the secondary containment solution as a safe haven for hazardous liquids that might spill or leak from the main container. A more formal secondary containment definition is that it is a solution designed to create a physical barrier for discharged hazardous liquids between the primary container and the environment. Hazardous materials include oil, diesel fuel, gasoline, adjuvant oil, hydraulic oil, vegetable oil, crop oil, and animal fat. The usual primary containment containers include storage tanks, transportation vehicles like tankers, pipes, and various other equipment.

If you store and/or transport hazardous liquids, you are subject to a variety of government laws and regulations. The overarching goal of all the laws and regulations is to prevent chemical spills from polluting the ground and reaching any bodies of shoreline waters and navigable waters.

Unsurprisingly, there is a dizzying array of laws and agency regulations at the federal and state levels. The state requirements are more detailed in terms of protecting the local environment, but they begin with the larger federal requirements for secondary containment.

Rules, Rules, and More Rules

We live in a world of rules and more rules, especially concerning hazardous liquids. The important federal authorities for secondary containment rules are the EPA and OSHA, and they operate with authority from legislation such as the Resource Conservation and Recovery Act (RCRA), the Clean Water Act, and the Occupational Safety and Health Act. By adhering to the environmental laws and regulations, you are also meeting OSHA requirements for protecting your employees from exposure to spills. All laws are codified in the Code of Federal Regulations (CFR).

Environmental Protection Agency’s Portable Container Rules

The Resource Conservation and Recovery Act (RCRA) addresses the EPA’s authority to regulate containment and secondary containment systems. Interestingly, the EPA refers to containment under 40 CFR 264.175(b) but does not use the terminology “secondary containment” to refer to portable containers, such as PacTec’s spill containment berms.

The requirements for a containment solution are:

- The base under the container cannot have cracks or gaps and it should not be vulnerable to leaks, spills, or precipitation.

- The base must be either sloped or designed to enable draining and removal of spilled or leaked chemicals or precipitation.

- The containment solution must be able to hold a minimum of 10 percent of the volume of materials stored in multiple containers or 100 percent of the volume of the largest container, whichever is greater.

- There should be a way to prevent rainwater or other liquids (called run-on) from draining over land into the containment system, unless the containment system has enough capacity to contain the run-on.

- Any excess capacity required is in addition to the minimum required 10 percent capacity.

- Any leaked materials and accumulated precipitation must be removed.

The EPA also specifies under 40 CFR 264.193(b) that secondary containment systems must be able to prevent the discharge of accumulated spillage or leakages into the soil, surface water, or groundwater. The regulations continue to describe some basic requirements for the secondary containment system, which include its thickness and ability to handle various stressors, such as driving on and off berms.

Clean Water Act and Oil Pollution Act

The Clean Water Act is a law designed to regulate designated pollutants into water. Navigable waterways include rivers, lakes, streams, wetlands, wet meadows, natural ponds, and play lakes.

The Oil Pollution Act gave the EPA the right to require large oil storage facilities and oil vessels to develop a response plan for large discharges. The type of secondary containment system and the secondary containment volume requirements are elements of the response plan.

Oil is defined as:

- Fuel oil

- Petroleum

- Sludge

- Oil mixed with wastes

- Oil refuse

- Non-petroleum oils

- Synthetic oils

- Mineral oils

- Oil and greases

- Animal fats

- Vegetable oils

Environmental Protection Agency’s SPCC

The EPA’s Spill Prevention, Control, and Countermeasure (SPCC) in 40 CFR Part 112 has very specific secondary containment requirements that specifically address oil defined by the Oil Pollution Act that spills into waters protected by the Clean Water Act. Oil spills threaten soil, animal life, and humans.

You are required to develop an SPCC plan for secondary containment if:

- Oil storage capacity is more than 1,320 gallons in all types of storage equipment, including containers, tanks, portable totes, drums, transformers, and any other electrical equipment that is oil-filled.

- Non-transportation facilities with an underground tank storage capacity of more than 42,000 gallons, i.e., oil refineries, oil rigs, drilling platforms, truck oil tankers, railroad cars, oil pipelines, and waste treatment facilities.

- Oil spills or leaks onto navigable waters, coastlines, or shorelines is a real possibility.

- Sites with less than 10,000 gallons of stored oil can self-certify they have had no spills; otherwise, the plan is certified by a Professional Engineer.

- The SPCC plan will include operating procedures to prevent oil spills, control measures to prevent the oil spill from reaching any water source, and containment and cleanup measures should the oil reach a waterway.

In your SPCC plan, you will need to describe your secondary containment solution. One tool that can simplify choosing a containment solution is the secondary containment volume calculator described under the volume capacity section below.

OSHA

As if those are not enough rules, you must also protect the safety and health of employees from hazardous material spills and leaks. OSHA’s requirements are found in CFR 1910.120, and first in order is the spill containment plan. The containment plan must meet OSHA standards, which require the containers used for containment and cleanup meet EPA and OSHA standards. OSHA requires the secondary containment meets the EPA volume requirements.

All About Volume Capacity

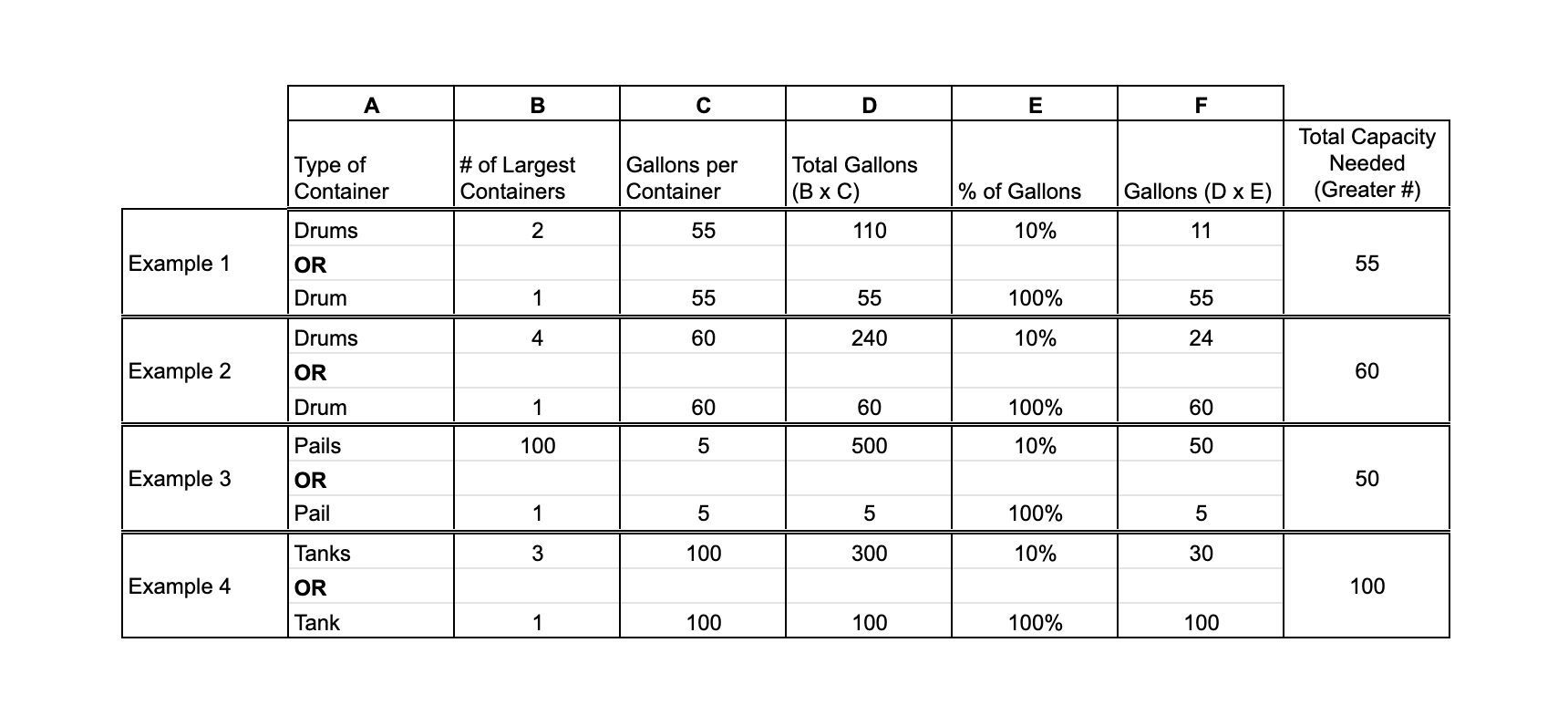

The myriad rules are one reason PacTec has designed a variety of secondary containment berms. Knowing how to calculate secondary containment volume is important. You need to dust off some basic math or simplify life by using a secondary containment volume calculator.

Remember, when calculating the capacity of spill containment berms, you need the ability to contain hazardous materials equal to 10 percent of the volume of materials stored in containers or 100% of the volume of the largest container. You then choose the volume that is greater.

1) The formula for determining the amount of liquid each container holds is:

Length (L’) x Width (W') x Height (H’) x 7.48 = Sump Capacity or Gallons per primary container

2) The formula to determine the secondary containment volume requirements is:

10 percent x total system gallons or 100% of the largest container in gallons, whichever is greater

There are online EPA worksheets available to ease the calculation process, along with example calculations. The following worksheets offer a secondary containment calculator for different job site setups.

There are online EPA worksheets available to ease the calculation process, along with example calculations. The following worksheets offer a secondary containment calculator for different job site setups.

- Single vertical cylindrical tank inside a rectangular or square dike or berm

- Multiple horizontal cylindrical tanks inside a rectangular or square dike or berm

- Rectangular or square remote impoundment structure for an aboveground tank storage facility

- Constructing new secondary containment for a rectangular or square dike or berm

Meeting Government Requirements With PacTec Secondary Containment Berms

It is a bit overwhelming ensuring your business understands and meets the complex secondary container requirements. PacTec cannot emphasize enough that precisely adhering to the various laws and regulations is crucial to avoiding hefty fines and maintaining an excellent reputation for environmental sustainability and protection of human health.

You can use a secondary containment calculator with the help of PacTec professionals who have expertise in figuring spill containment berm requirements and can supply the ideal solution. It’s easy to contact a sales representative in your U.S. region and begin the important compliance process for secondary spill containment.